I always make my own take down sleeves out of some steel pipes. Formerly I did them with a 90° cut, nowadays I prefer a 45° on the inner pipe (which is for the upper limb). When you make the bow asymmetrical (1″ above and 3″ below geometrical center for the handle) you will end up with two pieces, the upper and the lower limb, nearly same length. This maybe of interest when you storage the limbs in a flightcase or something similar.

Let’s start:

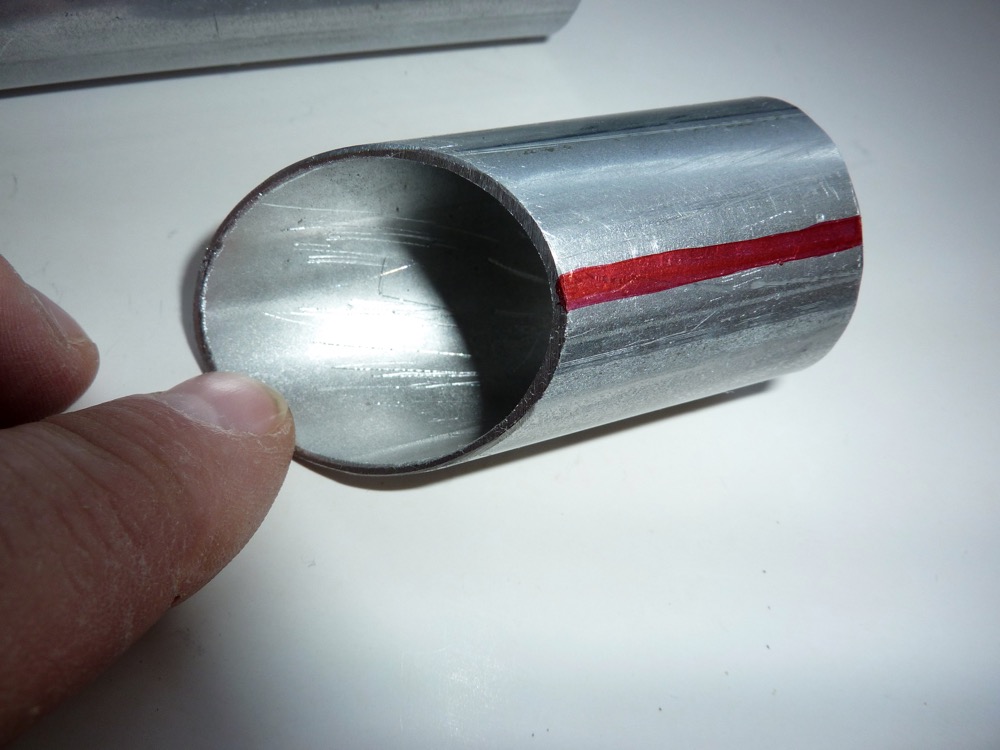

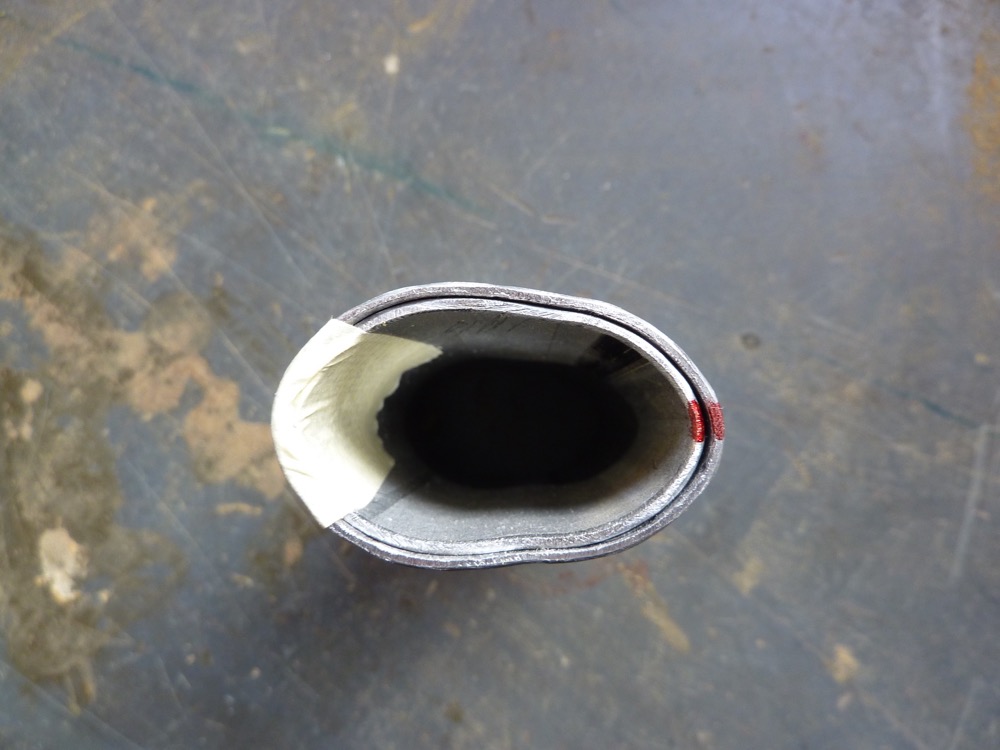

We need two matching pipes, I have for the outer a diameter of 38 mm and for the inner 35 mm. Both have walls of 1,5 mm, so the inner pipe fits excat the outer. The outer is cut 90° and 100 mm long. The inner at one end 90° at the other 45° , length is in middle 50 mm. Mark (here red line) the shortest distance, this is facing to the archer or simple it is the belly of the bow. Put it in the outer pipe and fix it with a piece of tape. Now mark also the outer pipe (red line), we neeed this line for orientation. Next step is to get the thing in the vice, red line up and exact in the middle. Some wooden blocks are useful to get the pipes absolut horizontal in the vice, of course they are removed before we ress with the vice. The first round is to get an oval, then clamp asymmetrical (using a thinner block) for an egg shaped cross section. The angle of the inner tube has changed a bit, because of the transformation. A belt sander or a good file will bring that inner sleeve in form again. That’s all – not that difficult!

5 Comments

Where do you find pipe with these measurements?

Ryan, I get mine from a junkyard for free.

Hi Simon, Thanks for posting this how to. Have you seen any markings on the metal pipe you are using? It looks to me like you have what is nominally called 1-1/4″ and 1-1/2″ EMT (metal conduit). If that is the case, you’ll have about 1.5 or 2mm of difference (or play) in the fitting, which you make up for by having it wedge into place. Does that sound about right?

Hi David,

I haven’t seen any marking on the pipes I use – but to be honest I haven’t searched for any. As mine come usually from the junk yard, I get often different diameters.

I search for a nearly matching combo and file the smaller one until it fits perfect with no play. Control the larger one, if it is a welded pipe you have to file out until it is perfect round inside. Polish the smaller one, stick together and squeeze into the oval you like.

Hi! I have found that trampolines support have the exact same diameter, 35 and 38 mm.They work well, just be warn that welding are sometime weak. Here is a bow made from this stuff ;https://www.youtube.com/watch?v=Dkzp9ts4UPM ( pics at the end)

Émile