Here is an interesting little bow, at least for me – haha. This bow is made with akinda prefab sinew backing, will say the backing is applied in one single piece. The backing of that bow was first on bow (No. 13), see here.

Here the sinew was applied conventional. It was thrown off with a loud bang while drawing obviously because of poor preparation at the back. I saved the backing strip and had it laying around for years. This year in August I thought give it a try again on a fresh roughed out plains type. The dried out strip was soaked in water for one day, the bows back carefully prepped, the strip applied in one whole layer, and …. it came out great!

I’m really thinking we should do more experiments in that technique, I read somewhere Koreans do it in a similar way.

Well back to the bow. The sinew backing is quite strong proportional (⅓ to ⅔) to the wood thickness, which is perhaps the reason for the cracks on the belly, they appeared while sinew curing. Tillering this bow out was easy and done in minutes, as the osage stick was near dimensions before I got it backed. The belly cracks were filled with thin super glue – excellent stuff! <the tips are secured with additional sinew wrappings, painted with red ochre. Forgot to say the sinew backing is all over the limb’s sides. The sinew had become nearly transparent, when the light comes from the right angle you can see the wood of the back shining through. Hard to make suitable pics.

The handle is red and black flannel, held in place with a linen thread. The zigzag on the back is painted with earth pigments and particularly sanded off after drying. I like the ‘used’ look, hope the fresh appearance of the cloth will assimilate soon.

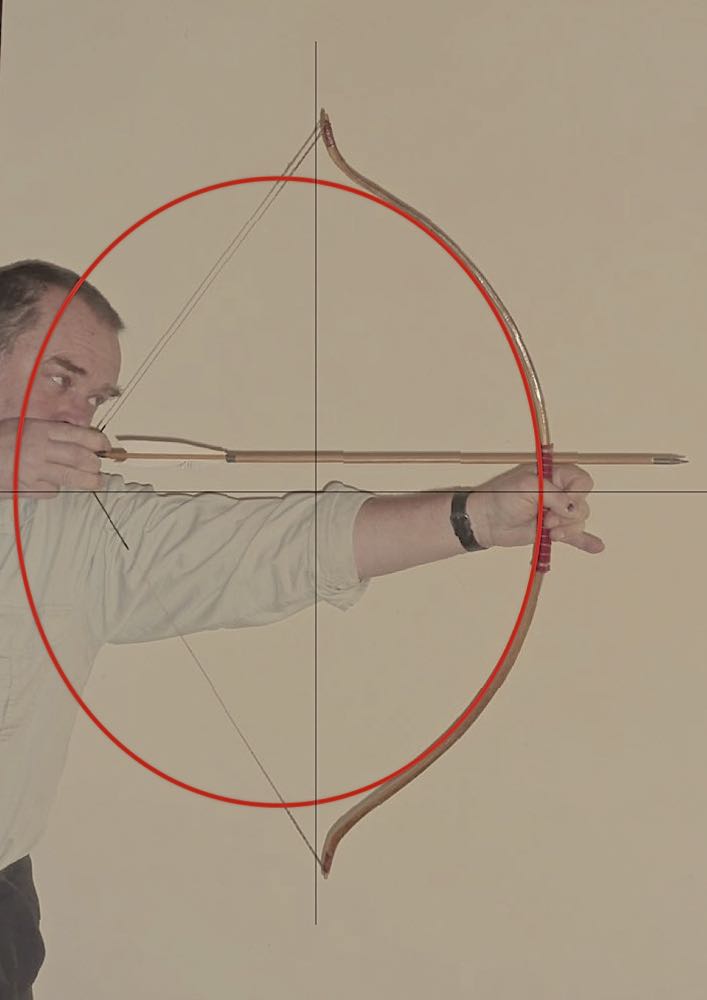

I found a nice bow in that manner in Baldwin’s book, but I will not call mine a replica of this specimen. My bow has short static recurves, I haven’t seen that sharp on originals. These short statics causes a smooth draw out to 24”, maybe there is a tic more available.

This bow has a reflex of 5¾”, immediately after unbracing it is 5¼”, coming back in a few minutes. I’m very pleased with that.

I like this bow very much, it has lot of early drawweight and is a really snappy little devil.

Ah, forgot to say the thing is 41″ ntn

Lot of reflex

short sharp statics

lower limb

upper tip

sideview limbs, transparent backing

details painting

2 Comments

This is great news! I just had a bow fail in a similar manner. It delaminates between the sinew and wood. Both remained intact. Was not sure what to do with it, so I just set it aside for awhile. I think I will try what you did with your little bow. Thanks!

Hi Jon,

glad I could be helpful. I did that meanwhile 3 times successfully on three different bows. Just keep your eyes on the sinew, the right moment is when it fully soaked and doesn’t tear apart.

Good luck!