HLD – a new progressive design for selfbows?

This is an article I wrote for the Primitive Archer Magazin. It was published in 2016 in volume 24/issue 5.

Stash of finished HLD bows viewed on belly side

Stash of finished HLD bows viewed on belly side

- What is a HLD bow

HLD stands for Hollow Limb Design. I didn’t find a better terminus. It means that the bow limbs are not flat or convex (rectangular or elliptical cross section), but concave at the belly with a high crowned back – a cross section like a boat.

Typical cross section of a HLD

I came to this design more or less by accident. Once I came over a stave with a very changing crown (depth). To get it matched I could have narrowed it on the sides, but then the front profile would have a changing width. Not good. Therefore I decided to give a hollowed out limb (hollowed out only in that section) a try and that was it. It did work, no chrysals appeared. Step by step I came to the insight a complete hollowed out working limb would have a lot of advantages.

IMO a hollowed out limb makes only sense in the working part. In stiff parts of the limbs other cross section shapes are more usefully, especially stiff outer limbs/tips. A triangular or eiffeltower profile (depends on the wood species and quality) is the better choice to save mass.

A good transition of a hollowed out limb into stiff outer levers can be achieved with building up a tapering ridge in the middle of the belly

Also snakey HLD bows can be made, the most important thing is an even crown, this one is spindletree (euonymus europaeus)

- Results, longevity

I have made about two dozen HLD bows so far. It should be more to get funded, more precise results. I began the HLD when I remember right in 2010. Some bows were gifted away, some sold and some still in my possession. I didn’t hear of a failure so far, the bows are still in use (except one elder because of bad tillering). I didn’t notice any chrysal or fret, esp. at the ‘belly ridges’(except one staghorn sumac – which I call a non-bow wood). Never had a vertically splitting, even not in this one where the hollowed out is extreme.

Golden chain tree take down with a cross section of more than a third of a circle

Here is an interesting comparison of two bows (both 40#/28”), the results really astonished me. The first is an osage static with extreme mass saving design and really skinny tips, the second is an elder straight stick with my probably best HLD so far. Both bows are in my wife’s possession, she draws about 26”. Both bows have the same length. On both bows she shot the same arrow through a chrono. Believe it or not, the elder is 12fps faster (average) than the osage.

Comparison of an osage static with an elder HLD straight stick

You can find more pics of both bows and info in the Bows section here:

How is it possible that the elder is explicit faster than the osage? In my experience a static recurve is per average about 10 or more fps faster than a straight stick. And osage is the best bow wood ever and this one is really not overbuilt. The determining difference must be the different mass of the whole limb. The hollowed out limbs of the elder are way lighter than the skinny osage static and/or more energy storage.

- Advantages:

Lower limb mass, shallow outer draw curve, lower limb stress, less set

The HLD allows a limb with lower mass compared to flat or lenticular cross section by a given draw weight. Think on folding a sheet of paper like a U, everyone knows it will stiffen. Or think on mass saving building or bridge constructions, the folding of components have massive influence on the mass and the wingspan.

The lower mass of HLD bows causes a faster return of the drawn limb, more energy on the arrow – a better cast.

HLD bows have a different f/d curve compared to flat bows. There is a steeper curve in the beginning of draw and a milder increase at the last inches, because of the flattening out. Compared to a conventional bow with same draw weight the draw curve of a HLD is flatter in the outer parts of the draw. The geometry of the HLD draw curve shows that these bows can store more energy than bows with a more linear draw curve.

Exaggerated profile sketches to show the idea behind

I will not say there is something like a ‘let off’ (like in wheelie bows), but the limbs thickness differs while drawing the bow. You know the limb’s depth is much more critical than the width. Double the width and you get a bow with 2x draw weight. But double the depth you will get a bow with 8x the draw weight. Just a little difference in the limb’s depth (flattening) causes a great effect.

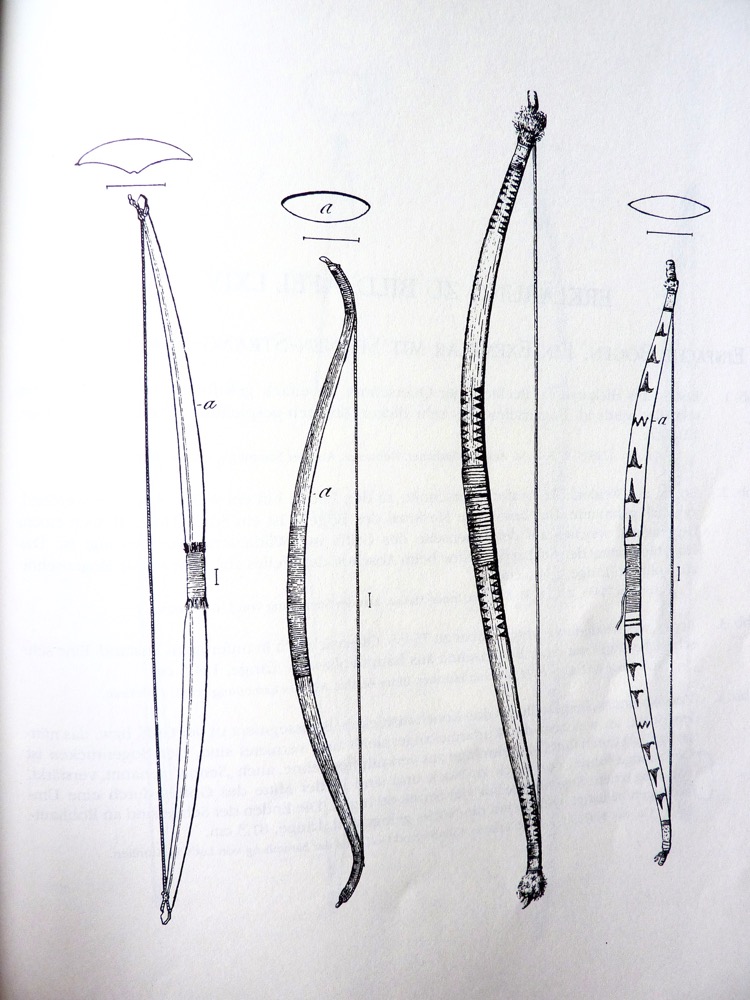

Comparison of two different limb profiles

Just to show the coherence or principle, in this sketch both rectangles have the same area. The second is 75% as high as the first but as 133% as wide as the first. Now let’s assume this is the cross section of two bows. What we get is the first is as 1.5 x as strong as the second. Or in other words the flattening out of a HLD limb while drawn provokes a decreasing draw weight. Well it is not so dramatic like in the sketch above, but you get a feel that a little change in the cross section profile has already a big influence on the draw weight and therewith on the comfort of draw.

Drawing a HLD bow always reminds me on spring steel, the draw is very smooth and comfortable. You really can feel the different behavior of these bows.

In my opinion the limb’s belly has lower stress compared to the flat profile (see my sketch below). The flattening out causes a tension horizontally on the belly side, perhaps this allows ‘more room’ for the cells to compress vertically when the bow is drawn. Same on the back, the ‘normal’ tension vertically and additional compression horizontally.

Hard to proof, but I think HLD bows get less set compared to conservative designs. At least it is my experience. A possible explanation is the combination of horizontal and vertical forces on back and belly as mentioned above. Less stress in the outer ridges maybe a possible argument for low set. Maybe I simply got less set, because the tillering out is slower and more precise or more carefully.

- Bow wood

I have done HLD successful with osage, elm, ash, yew, hazel, golden chain tree (laburnum), european spindeltree (euonymus europaeus), dogwood, plum, elderberry (sambucus), juniper and some others.

At least hazel is marginal bow wood, but I had a surprisingly good result with that specific bow, so I cannot say HLD needs a highly interlocked grain like elm or hickory.

I have made some HLD osage, but only with a mild HLD so far. The back wasn’t high crowned enough to squeeze out all the effects. I’m still waiting to get my hands on a suitable osage sapling to make static recurve with bending parts in HLD.

- Reference

I know about Bhutanese bows, made out of boo slats. They use it inside out; the rind is belly surface tillered at the sides and on the concave back. A quick made, really primitive bow. Maybe here are similar principles working like at HLD bows.

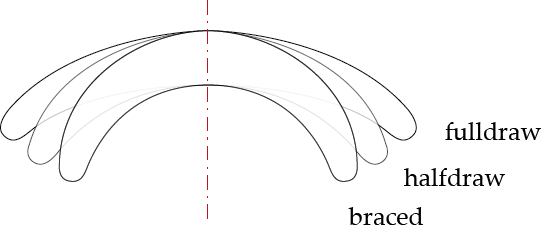

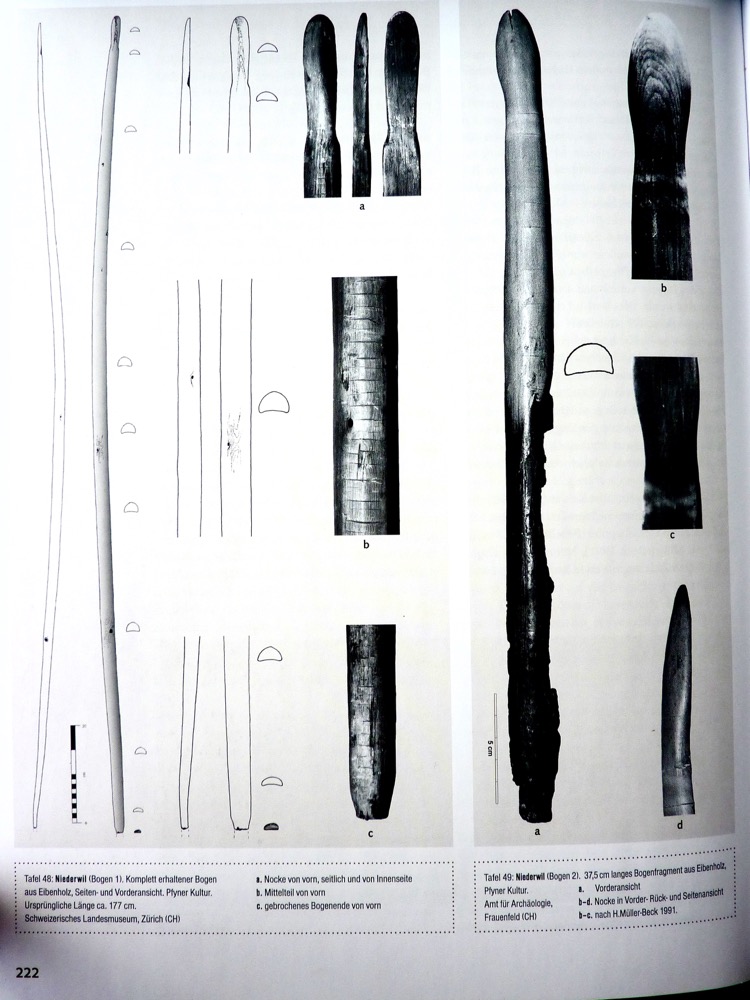

I have not found a historic reference till now. There are some examples with a furrow in the middle of the belly. Let me name two:

Left: A bow from Switzerland: (publ. in: J. Junkmanns: Pfeil und Bogen)

Right: Bows from American West coast, look at the left one: (publ. In: Otis Tufton Mason: North American bows, arrows and quivers)

I really do not know what the reason for that furrow is. Decoration? Stiffening out the limb, like the furrows on plains arrows does? These are interesting bows for sure, but not what I mean with HLD.

- How is it worked out

This is definitely a design not for beginners; the limbs should work not only in the vertical direction but also horizontally. The whole system of the bow must be in balance. Probably best is: shape front profiles first, begin grooving out. Control thickness with a caliper (see pic below). My caliper is a quick and crude made thing, but works perfect. A wooden slat and an aluminum profile are simply taped together. On the slat is a glued on nut and allows the pencil to adjust. The glued on wooden point on the aluminum rides along all humps and bumps of the stave. The whole thing is a bit springy so that the pencil’s point doesn’t break.

I do my ‘floortiller’ not on the floor. I’ve made me a pair of leather shoes for the bow tips hanging on a paracord. The cord is hooked in the opened vice and the bow is pulled back. So I do my ‘floortiller’ horizontally. Advantage is: I can watch the movement of the whole bow orthogonally and I have one hand free. In the further stages of tillering the free hand can be used touching the belly of the bow while drawing with the other hand. You can feel the flattening out effect, control on all portions of the limbs. The flattening doesn’t mean a HLD limb changes to a complete flat limb. But, if properly made the curve opens a bit and becomes wider. In other words you are aiming not only for a taper from fade to tip but also from middle of the limbs to both sides (cross section).

The groove begins in the fade and is increasing where the limb begins to bend. I usually let the outer limbs stiff, therefore the groove tapers out way before the stiff part.

The gooseneck scraper is probably the most important tool for this job. Net grit folded around a melt glue stick makes an effective tool for sanding down in the concave groove, it follows nicely the humps and valleys of the natural grown wood.

Here are the tools used for grooving out the limbs:

Gauge, bent gauge, goose neck scraper, melt glue stick + net grit, right: homemade caliper

Detail on rough worked out profile on a plum stave, leaving the edges sharp gives a good guideline for the thickness of the ‘walls’. I leave them first parallel and go then to taper using my caliper and the goose neck scraper

- Notes for the design

Here are some thoughts and experience for those who want to try.

Half the way is searching for a suitable stave. A stave with a high crown is needed. The crown should be as even as possible over the whole limbs. Of course I prefer a ‘clean’ stave with HLD. Struggling around with knots, twist, doglegs or other ‘character’ may be result in a really challenge.

The depth of the limb (measured over the hollow) compared to the width should be in the ratio of about 1:3. The curved wall of the limb must be thin enough to work (flattening out). The two ends of the wall should have no edges and must be sanded round to prevent excessive stress. Looking at the middle of the cross section of a HLD limb (see sketch above) the thickness should taper out to the ridges. Here is the thinnest portion of the cross section. If there is no taper outward to the ridges, the drawing of the bow would cause excessive stress in the middle and provoke splitting lengthwise.

A HLD bow should be shorter and wider than a ‘normal’ bow, just to get the effect of limb flattening out. If it is as long as normal the effect isn’t that dramatic. I know about the ACS fiberglass bows with a parallel belly and back, the cross section is a stiff segment. This construction saves some mass compared to a normal rectangular limb construction and is probably good for bow stability.

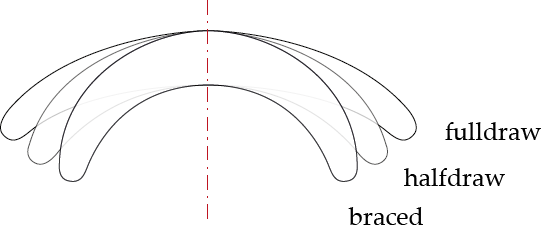

But, the idea behind a HLD bow is that the cross section of the bow limb transforms its cross section shape in the different phases of drawing the bow. I mean the limbs are not only working vertically, but do also horizontally. You all know the limb’s strength increases exponentially with its thickness, double the thickness and you get 8x strength. Will say the increase or decrease of thickness changes the strength already in little amounts. Now look at the sketch: what happens while the limb is being drawn? It is getting a little wider (w1, w2, w3) and the flattening out causes the decrease of the thickness (d1, d2, d3). The more you pull the bow the more the limb flattens out.

For further information of my HLD bows, search for HLD bows on my site or on the PA forum. Or just google ‘HLD bows’.

- Outlook

I hope you got interested in this design and encouraged trying it. As said above there are a lot of things to discover. I will definitely continue working on this design, trying to improve my skills and the layout of these specific bows. I’m absolutely convinced here is a great potential with many advantages. You will find my attempts from time to time posted on the PA forum and on my site.

I’m really interested on results of others; you can contact me here or via the Primitive Archer Forum (aka ‘simson’).

A bunch of new HLD bows in different phases of work

20 Comments

Hello Simon,

thank you, this is a very nice description of the HLD design. The bows look really great. I still wonder how strong the “limb-flattening” effect is in practice. Can you make some measurements of the depth at brace and full (or at least half) draw on one of your bows?

Best regards,

Pablo

Hi Pablo,

The measurements are very difficult, I tried to do so, but I will not hold the bows on fulldraw that long. But I estimate the flatting out up to 3 mm, which is an enormous difference in thickness. Perhaps I can build an apparatus for that when I find some time.

If you are also working on HLDs please let me know your experience.

Working on HLD is not for beginners, you should have a few bows under your belt. I got not much feedback, but Carson and Weylin made a bow with this design. Both have a website, go to ‘Links’.

Hello

thanks for your post. I read all your post and reply on PA. Even if i didn’t understand perfectly (i’m not anglophon so..) but it was amazing. I’m trying to make HLD myself but pictures and text is nof enough for me. If it’s possible can you upload the video how to make HLD bow or at least shooting videos? I really want to see how the limb works.

and few little question. Can i use bamboo for HLD bow? Maybe bamboo split verticaly?

and about amonia fuming.. here where i live i can’t buy concentrated amonia without licence. i can buy 2~3% but i think it’s too low. Is there any other way to fume the bow? I already tried with baking soda but it doesn’t work well..

if i fume the bow with amonia is there any change of bow’s property? or just change of color?

thanks in advance

Hi fellow (I see no name … ), don’t know where you come from but assume you are French, right?

If so you can easily order ammonia in Germany, there are several suppliers and it’s quite cheap.

Let me know if you need a link. 2-3% do not work!!!

Video: sorry to say that, but I never did a video

Bamboo: maybe possible with a thick walled species. I’m interested what you get out with that project. Maybe vertically splits can be avoid with a rawhide or linnen backing on the bellyside. Mmmh, I really must say I’m locked! Will do some experiments also!

Good luck with your projects!

Thanks for reply

Half correct. I live in France but i’m korean. But how do you know that? I will make bow when i go back to my country (there is no space for work and i can’t find material also. does french people make or enjoy primitive archery too? maybe i live in small town but there is only one archery club and they do competion bow)

Anyway i want to see your wonderful bows continuously. In korea (south) normally we make primitive bow with high crowend tree (sapling, brache, shrub etc) or bamboo so your infromation about HLD is very interesting.

Kind thanks

Hak

Hello Hak,

It was just a guess, haha, but as you said half right.

In France is a community of primitive archer and bowyers, too. Just do a google search and you will find.

Btw. the Corean composite bow is most beautiful and high end bow ever, at least for me. I was lucky enough to hold some of them, also ancient bows, in my hands.

Never seen a self bow from Corea, send me some pics if you have some.

Nice to have you here Hak!

Highly fascinating!

How do you think about hld bow with carbon fiber?

I’m not interested in fiberglass (fg) or carbonfiber bows. But for those laminate fg guys: In my eyes all possible designs (side view) are made and there is no more innovation. The only thing to change is the cross section of a bow, and there are a lot of different things to test out, especially fot laminated bows.

Please, make the video and upload to youtube.

sorry, I have no oppotunity for video ….

Is it possible to make hld bow with pvc pipe?

This looks fascinating. I have been passing on small diameter staves just because I do not like the looks of high crown bows. I am now exited to find one and try this. Beautiful work. Thank you.

Hi Dave,

thanks for your note. Yep, that HLD bows are exciting. I’m curious what you are doing with this design – let me see some pics of your work when you got them finished.

It is not an easy way, but the performance of this bows is really on top level.

5 and a half years later, I add my comment here.

In general, the bowmaking and primitive archery communities are pretty strong in Europe. I’m German and that is gonna be my bias, but there is a big and a smaller bowyer forum in German. It used to be a real haven, but times have changed. You see lots of German bowmakers participate in English forums or make youtube videos im English. That’s because that is where people culture of bowmaking is the most innovative, progressive and advanced.

France is one of the few placess that even allows bowhunting. Even for foreigners! The requirements are reasonable, too.

Hello Marc,

I make this website in English to reach as many interested people as possible. I have many contacts scattered all over the world and only with English communication is possible.

Hello,

Your work is amazing. I stumbled upon this website as I was making a 52 inch vine maple bow (has high crown, small diameter) and running into the issue of the sides being too thin at the width I needed.

Anyway, my question is around heat treating the belly. I see you use heat to bend wood on some of your hollow limb bows, but have you had success with heat treating the entire length of the belly? I ask because I am hoping to increase the poundage of said maple bow (which I have made into my first hld bow and it came in a little lighter than I intended).

Apologies if you mention this elsewhere and I did not see it.

Thanks.

Hi Lucas,

we don’t have vine maple here, so I can’t say anything about it from my own experience. But I know it is very good bow wood.

So let me suggest to go to the ‘Primitive Archer Forum’, Catergory ‘bows’ and ask there. I’m absolutely sure you will get some good advice from my comrades there.

besides, I think the most carefully heat treating is the best. I mean it should be as evenly as possible.

A real HLD has thinned out limbs (to the sides), this will make it much more complicated to get a good heat treating. In other words: don’t burn the sides!

Good luck!

Hi, what do you think is the shortest reasonable bow length that you can build with the HLD? Like 90cm-130cm?

Hi Amrit,

I don’t know about what you are after.

Of course you can build a short bow with HLD.

But there are many factors you must have in mind, like drawlength, wood species, draw weight, width of bow limbs, sinew backing ….

… just to name a few.

Simon