You can see here:

- This is a making of a new static, how I usually do it.

- How I do steam bendings

- Corrections with heat gun

- Handle glue on

- Bone inlay as arrowpass

I’m aiming for about 60#. The stave is very nice, but a little twisted and a sabre

One side shows growth rings absolutely o.k., the other a bit thin – but I have to go with it. The stave was worked down to a growth ring several months ago, but there are some deep drying cracks on the outer limbs going through at least three rings. I hope, I could avoid them.

The stave is 61” long.

After the first clean up:

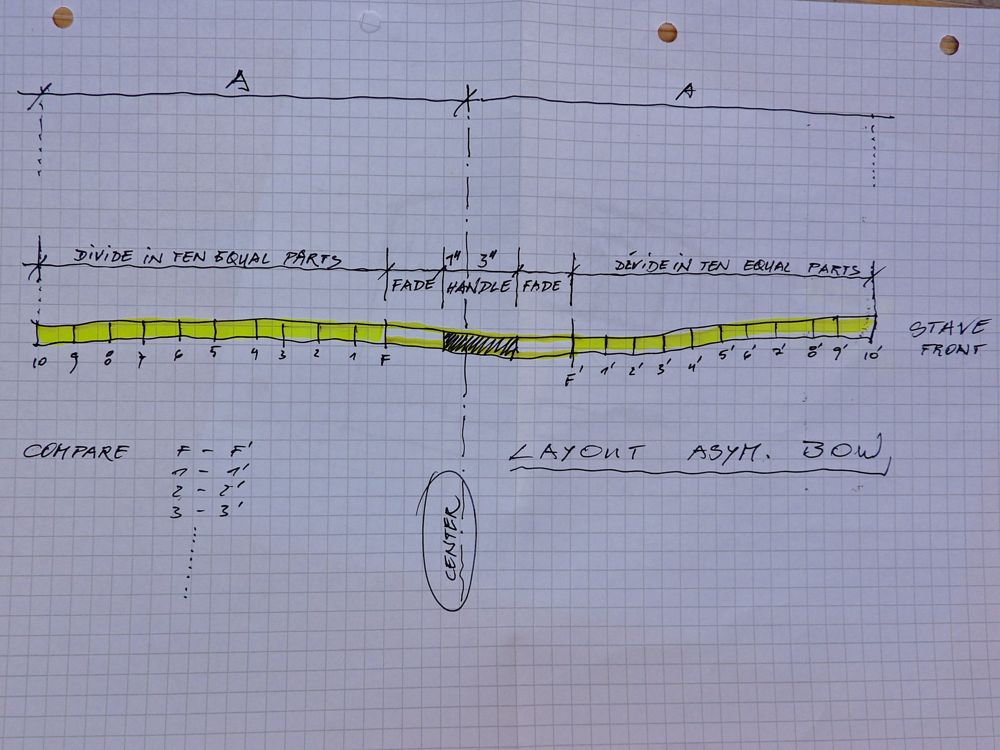

Lay out of handle, 1” above, 3” under center. Fades are marked 3” from handle. The limbs are divided in 10 parts and marked with a pencil. Of course the parts are different length in lower and upper limb.

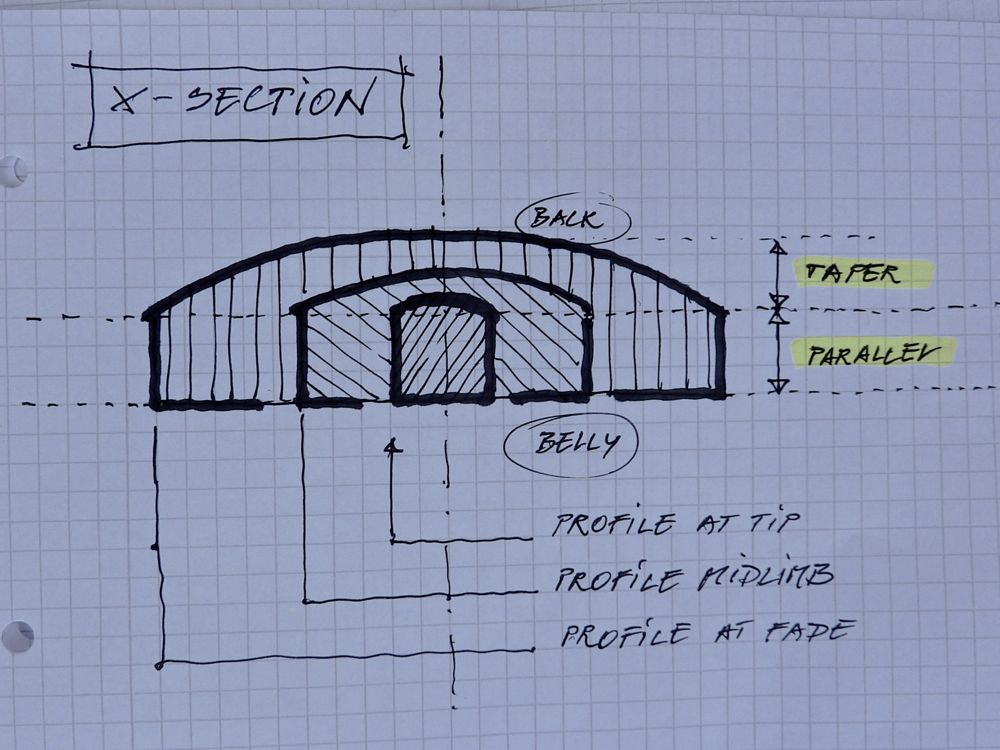

I do not mark a center line lengthwise the stave. I let the draw knife search the line. Using extra sharp blade makes it easy finding the grain. The result is a parallel stave (front) from fade to tip. From there on I make the side taper by fading out with long draws with the knife.

First one limb is worked out, how I like the front profile, then the parts (pencil lines) were measured and the other limb is made the same. I work here very exactly. My measurements are made with a vernier caliper. The thickness is only rough worked down to a parallel thickness, for orientation a parallel line is drawn on both sides of the stave. The limbs were tapering out to the tips to a square of about 5/8”.

here is the left over from the first reduction

Now for the recurving. The next pic shows my boiling machine, made from an electric cooker (from grandma), a cooking pot, an old plastic salad pot and a flex plastic tube (allows even boiling character staves). The stave is fixed in the tube with some cloth, so the steam and the heat remains in the tube. I heat the thing for about 30 min.

here is the simple caul (made in 2 min) from a plywood board. On the stave you can see the green line for rough thickness.

I use two short cauls for the recurves, this allows doing both recurves in one session. I let them cool down over night.

12 Comments

Hello Simon ,

My name is Mike and I am from the UK . First of all let me congratulate you on an absolutely fantastic website which is full of informative yet easy to follow instructions for various projects . I was particularly interested in the “Osage Static buildalong No 47 ” . This is exactly the type of bow I am intending to construct . Can you give me some advice regarding which other woods would be suitable for strength and elasticity , Maple , Oak , Ipe ? also I UNDERSTAND ABOUT THE FADES ETC BUT WHAT DICTATES THE RISER (HANDLE ) DESIGN ? Would you not have to have another piesce of thin wood fitted between the stave and the riser to help prevent the compression from loosening the riser ? Or will the fades do that job ?

Kind regards .

Mike

Mike,

thanks for your kind words!

Your question:

You can use nearly every wood you like, if it is not too soft. I myself have used a lot different woods, mostly i went for a contrasting wood like here. Sometimes I use leftovers from the same stave, so that it is hard to even see the glue joint.

Easiest way is to have sharp fades at the non bending part of the handle, otherways there is a risk for riser popping off.

If you cannot avoid, or in other words if you have to glue on overlays on bending parts: Use the best glue you can find (epoxi), be sure to have a smooth fading in (no aprupt transition).

Good luck for your project!

Simon

Hello Simon again ,

Just out of pure interest can you tell me why you think Osage is the best wood for bow making ?

Many thanks .

Mike

osage can handle the stress of tension (back) and compression (belly) best of all woods. You can make nearly all designs out of this wood. It is most forgiving if you make a mistake.

…. and it is beautiful wood!

Hello Simon ,

I hope you do not mind me asking these questions regarding bow making , but I need to understang certain things !

. Would it be practical to build a Recurve Bow with a Bamboo backing for extra strength ?

. And if so would I glue the Bamboo onto the main stave before I start to steam the bow to make the recurve / or would I do the stave and Bamboo separate and then glue them together ?

. Ideally , what thickness should the bow be after joining the two pieces together ?

. Would this combination benefit the overall use of the Bow ?

I hope you can answer my questions as I want to make a good job of making the bow !

Kind regards .

Mike

Extra strength: you can do, but you also can make a selfbow with high poundage

Steaming: before the glue job!

Thickness: belongs to the desired strength of the bow, watch my bows there are sometimes measurements noticed

I don’t understand the last question … sorry

Hello Simon ,

I have just noticed I think you said that the limbs are different lengths ???

. What dictates this / Why ?

. Which is longest upper or lower ?

It is a geometrical problem. The pivot point (where the pressure of your bowhand sits) should be also the place where the arrow should go out – impossible!

Best would be that this point is excat the middle of the bow, but you need some place for your hand and the compromise is to go with the handle 1″ above and 3″ below the bow’s center. Arrow pass is then also 1″ above. This makes the upper limb 2″ longer than the lower limb (handle is 4″).

Hello Simon ,

Thankyou again my friend , you have so much knowledge regarding Bow making and you have been a great help . That was agood answer to my last question so now I understand . Osage is difficult to get here in the UK , can you advise any British hardwoods that are good in compression and tension that are also good for steam bending ?

Thanks again

Mike

Elm, ash, black locust, cherry, apple, plum, walnut, …. +++

perhaps you should contact Derek Hutchinson (go to the Link section, there you find his website). As he is an Englishman, he can give better advise than I.

Hi

Browsing your site, What a gift you have !

I don’t understand why there is an automatic thickness taper when you follow the parallel line ?

Thanks

Manu

Hi Manu,

Look at the scetch (about in the mid of this buildalong), I think you will understand then what I mean.

Well, it works only when the crown on the back is continous along the whole limb length. On an absolut flat belly you can’t get that automatic taper. But it is much more easier to start thickness taper from parallel lines. Hope this works for you …