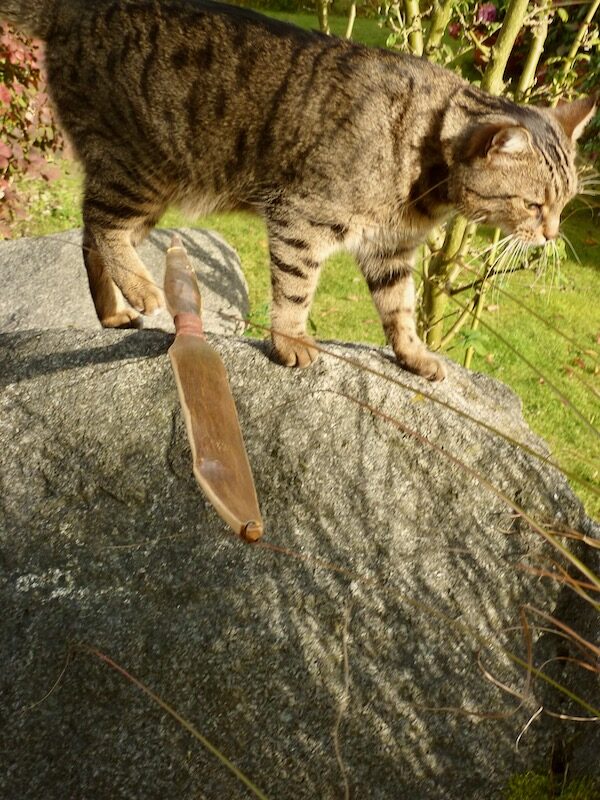

Simple hazel stick, with natural grown 2″ setback handle, stave was exact 2″ in diameter. This stick came out of a bunch of hazel staves I used to have for working with kids. Most of that staves were debarked – some not. This caused the problem. Someday I noticed bugs/worms on the barked ones. I immediadetely worked down the bark and saw that the bugs have already violated the first ring in some areas.

I decided to ignore that and give it a try. And this came out:

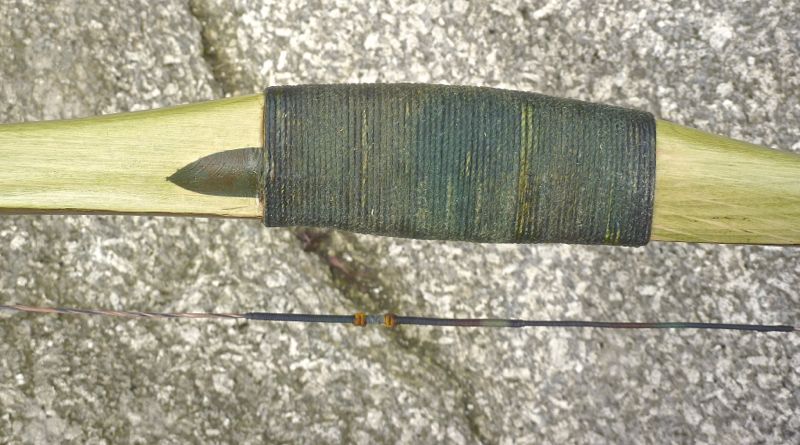

design is a long fade,narrow handle, stiff tipped flatbow. this little sapling had a high crown, for this reason I did again a hollow limb design to avoid narrow high stressed limbs. The bow came out very clean with surprisingly little set. Hazel is not the first choice as bowwood, but I’m very pleased with the performance of this bow!

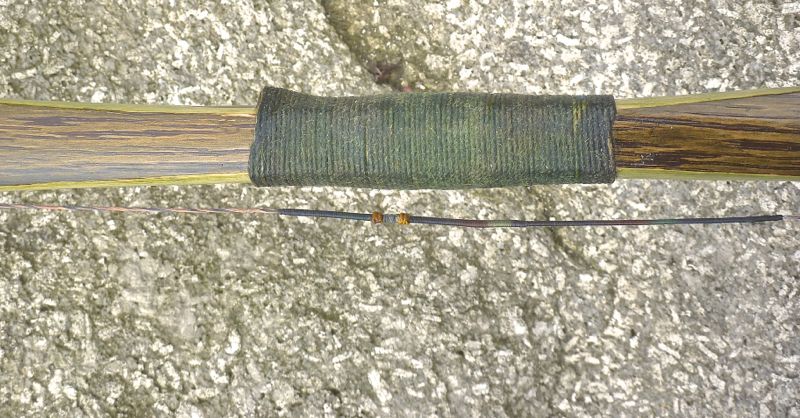

The bow is dyed with two colors (wet in wet), hemp handle wrapping also dyed, some cambium is left on the back to get the flickered appearance. Arrow pass is made of two color stone powder/epoxi, a little buildalong is posted a few weeks ago.

Overlays are cattle bone. String 6 strands 452X. Bow is 68″ ntn

No heat treating and no heat correction on that bow, was fun to make that one.

2 Comments

Dear sir,sorry I don’t speak Deutsch but let me tell you what I’m doing anyway.

I’m making a 45 inch short bow from hazel.

I’ve already tillered and am now at the seasoning stage.

I intend to season for 3 months in 3 stages.

Stage 1: place a block at the centre of the bow with the ends of the limbs tied tight and the block placed between the middle(handle) of the bow and a thick piece of iron to create the constant tension.

Stage 2 and 3 to use another two blocks further along the limbs against to more iron posts.

Then finally use two blocks the furthest against the limbs against two more (concreted in the ground)iron posts to increase yet more constant tension.

Each stage will be last 4 weeks.

In my garage.

My hope is the constant tension over time will create a significant enough bend in the bow.

I have an ability of a 46 IBS pull bit I want to increase this to 55+ over months of practice.

My main aim is this.

A short hazel bow with a strong pull power for its length.

I am at the start of the seasoning process.

I will have finished seasoning at the end of the year/start of of 2020.

I have already made 12 arrows for the hazel bow and intend to make another 12.

Tell me….what you choose hazel to make your particular bow with?

And could you give me any tips on any heat treatment,oils,dye or varnish I should use with it?

Thanks

John bicknell…..UK

John,

sorry to say that – but I don’t believe this is a good plan.

1. How can you tiller a bow when the stave is green?

2. Hazel is bow wood, but needs to be wider and/or longer than for example yew or osage.

3. I don’t know how long you are suspect the draw should be, a unbacked 45“ hazel (straight, not heavily reflexed) will make a 22“ draw length

4. To get a decent draw length, a paddle like design is a good option (see here http://primitive-bows.com/tag/paddle-bow/)

5. It is a good idea to let a stave season under reflex, but there is no way to create excessive reflex. Every wood can be bent to definite curve before it breaks, when you induce excessive reflex you will shorten the draw length

6. To make a bow that short and about 50# I would recommend a paddle design with yew or osage and a sinew backing

7. Finish: every hardening oil will work, such as tung oil, danish oil, true oil …

8. Heat treatment: works good with hazel, use a electronic heat gun, go for a slight brown color, a bow that short will be done in 30 min

Hope my words are useful for you

happy bowmaking and good luck!

Simon